We designed and developing piezo actuated electro-mechanical valve with minimum number of wetted parts. This valve use piezo actuation technique to operate valve and therefore it have advantages of precision, fast response over traditional pneumatically actuated valves. This valve can be used for various applications: Robotics, Aerospace, and Semiconductor Manufacturing.

This valve can be used as STOP VALVE & FLOW CONTROL VALVE both: The diaphragm of the valve completely seals the flow of fluid and therefore can be used as stop valve. The valve can be made normally open or normally closed depending upon requirement. Piezo actuation makes it possible to control flow through valve by controlling applied voltage to piezo.

An electro-mechanical valve is a type of valve that is operated through an electrical signal or impulse. It combines electrical and mechanical components to control the flow of fluids or gases in a system. Electro-mechanical valves can be actuated by different types of electric signals, such as a voltage, current, or a digital signal, depending on the design and application of the valve. The electric signal triggers the mechanical components of the valve, such as solenoids or motors, to open or close the valve.

A piezo actuator is a type of actuator that uses a piezoelectric crystal to produce precise, rapid mechanical motion. Piezo actuators are commonly used in precision positioning systems, such as in scientific instruments, microscopy, and nanotechnology.

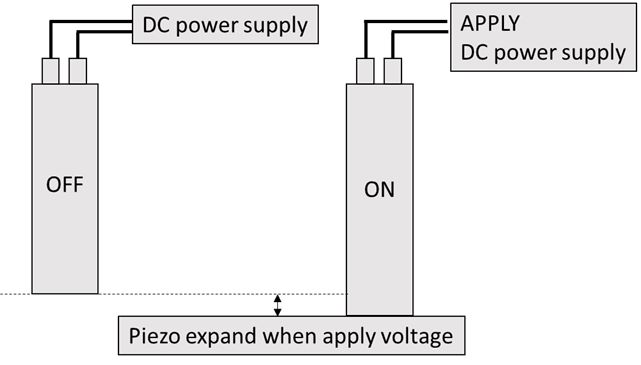

Piezo actuators work by applying a voltage to a piezoelectric crystal, causing it to change shape and produce a force or displacement. The crystal can be designed in various shapes, such as a stack or a bender, depending on the desired motion or force

A piezo actuator is a type of actuator that uses a piezoelectric crystal to produce precise, rapid mechanical motion. Piezo actuators are commonly used in precision positioning systems, such as in scientific instruments, microscopy, and nanotechnology.

A piezo actuator is a type of actuator that uses a piezoelectric crystal to produce precise, rapid mechanical motion. Piezo actuators are commonly used in precision positioning systems, such as in scientific instruments, microscopy, and nanotechnology.

A piezo actuator is a type of actuator that uses a piezoelectric crystal to produce precise, rapid mechanical motion. Piezo actuators are commonly used in precision positioning systems, such as in scientific instruments, microscopy, and nanotechnology.

Piezo actuators offer several advantages over traditional electromagnetic actuators, such as high precision, fast response times, and low power consumption. They are also compact and can be integrated into small systems, making them ideal for applications where space is limited

Piezo actuators are used in a wide range of applications, including optics, robotics, aerospace, and semiconductor manufacturing. They are also used in medical devices, such as precision pumps and valves, as well as in consumer electronics, such as cameras and smartphones, where they are used for image stabilization and autofocus.

Solenoid devices are the standard for electrically controlled pneumatic valves. However, piezo valves offer many advantages over their solenoid counterparts and open entirely new areas of application. Pneumatic valves made with piezo technology offer many advantages. They are small, lightweight, extremely precise, durable, fast, and save energy. Piezo valves do not need the energy to maintain a switching status, and therefore generate almost no heat. What's more, piezo valves can potentially be operated without any noise. Another key advantage is that they always work proportionally. Piezo valves can be a better alternative to conventional solenoid valves, especially in applications requiring directly controlled proportional valves. They provide gentle and safe speed control for pneumatic cylinders and work well in medical applications, laboratory automation, manufacturing, and even motor vehicles.

Piezo elements are electromechanical transducers. With the direct piezoelectric effect, a piezo element converts mechanical forces (pressure, tensile stress, or acceleration) into a measurable voltage. The inverse piezoelectric effect is precisely the opposite — a piezo element is deformed when a voltage is applied to it, thus generating mechanical motion or oscillations. Basic piezo elements can take the form of disc transducers, bender actuators, and piezo stacks.

An electro-mechanical valve is a type of valve that is operated through an electrical signal or impulse. It combines electrical and mechanical components to control the flow of fluids or gases in a system. Electro-mechanical valves can be actuated by different types of electric signals, such as a voltage, current, or a digital signal, depending on the design and application of the valve. The electric signal triggers the mechanical components of the valve, such as solenoids or motors, to open or close the valve.

Low energy consumption and no heat generation: Thanks to their capacitive principle, piezo valves require virtually no energy to maintain an active state. The valves do not generate heat if high-frequency control is not used (because that requires frequent switch-on energy). The energy balance increases along with the required switching frequency. Piezo technology is ideal for use in the “very-low-power” range of battery-powered devices (Figure 2).

Intrinsic safety: “Intrinsic safety” is increasingly specified as the required degree of protection for environments with potentially explosive atmospheres. An electrical system is intrinsically safe if the greatest amount of energy it can store is not enough to cause ignition of the atmosphere in the event of a fault. Piezo valves are an ideal way of meeting this requirement, which makes them usable in many potential applications.

Switching speed: Piezo valves can be incredibly fast, easily reaching the sub-microsecond range. These valves are often the best solution for applications where speed plays a decisive role. Such applications include high-speed sorting systems and closed-loop control circuits in general, as this type of circuit usually works better the faster the individual components react.

Proportionality: Proportionality is an intrinsic characteristic of piezo technology. Since ultimately all pneumatic processes in an application are analog, this is an unbeatable advantage — there is no need for pulse-width modulation and the associated noise problems as a means of trying to achieve a certain proportionality when switching solenoid valves. This means that piezo valves are very resistant to wear and need only minimal energy input. Combined with their short response times, the proportionality of piezo valves makes them well-suited to function as actuators for all higher-level control systems.

Anti-magnetic: Piezo technology can also be used without any risk of failure in areas with high magnetic field strength, such as in magnetic resonance tomography (MRT)

Minimal weight: The fact that piezo valve housings are usually plastic (without iron and copper) makes them very portable.

Low costs: This technology can be mass-produced if large quantities are required. For example, piezo-ignited lighters are available for very little money.

Long service life: When a system is designed correctly, piezo drives can achieve an unusually high number of operating cycles. They consist of a single solid-state working component with no wearing parts that might be subject to friction. It's important to note that these advantages cannot all be exploited at the same time in a single valve. Valves are generally designed for particular applications, and each would make use of its own specific benefits.